The Coax Gen2 Series Optimization Process – An Interview with Roger Kessler

August 2022

by Livia Weber and Roger Kessler

Our Coax series is a true classic. Originally designed by pioneer Kurt Scheuch, it has now been meticulously revised at the highest level by the PIEGA development team. I had the honor of interviewing Roger Kessler, Head of Research and Development at PIEGA, to learn more about the targeted refinements in this unique optimization process.

ROGER KESSLER, HEAD OF RESEARCH AND DEVELOPMENT

„I like to compare the Coax Gen2 speakers with a Porsche 911 – both are fascinating in their own way; they’re tricky to build but bring all the more fun!“

What does the Coax series signify for PIEGA?

The Coax series is probably the most important one for PIEGA because it shapes the perception of our brand like no other. Meticulous Swiss craftsmanship and its singular coaxial ribbon embody the essence of what PIEGA stands for. With four 22 cm woofers, the Coax 711 in particular, leaves no doubt that Kurt has created a remarkable loudspeaker and a true classic.

The Coax has been a significant revenue driver for many years. Nonetheless, or perhaps precisely for that reason, it was time for a complete makeover.

What part of the Coax series was optimized?

Everything! *laughs*

No, seriously, every single aspect has been analyzed, scrutinized, and improved.

The most obvious being its new size and shape to create an even larger cabinet volume. The cabinet has been acoustically enhanced so that the rear sound proportion in the lower midrange is better absorbed. The additional volume helps produce clean, dry, and thus full-bodied basses.

A larger cabinet inevitably leads to adjustments in the “Tension Improve Module” (TIM). As a result of the larger surfaces, the cabinet tends to resonate more, which has an immediate impact on the sound quality.

What specific changes are you referring to?

Until now, the “Tension Improve Module” (TIM) put the speaker cabinet under controlled tension by applying pressure to the inner walls, which effectively calmed cabinet vibrations.

The new TIM2 is put under tensile stress and positively bolted to the cabinet for even better results. This ensures the rigidness of the construction and keeps the bass as it should be: dry and accurate.

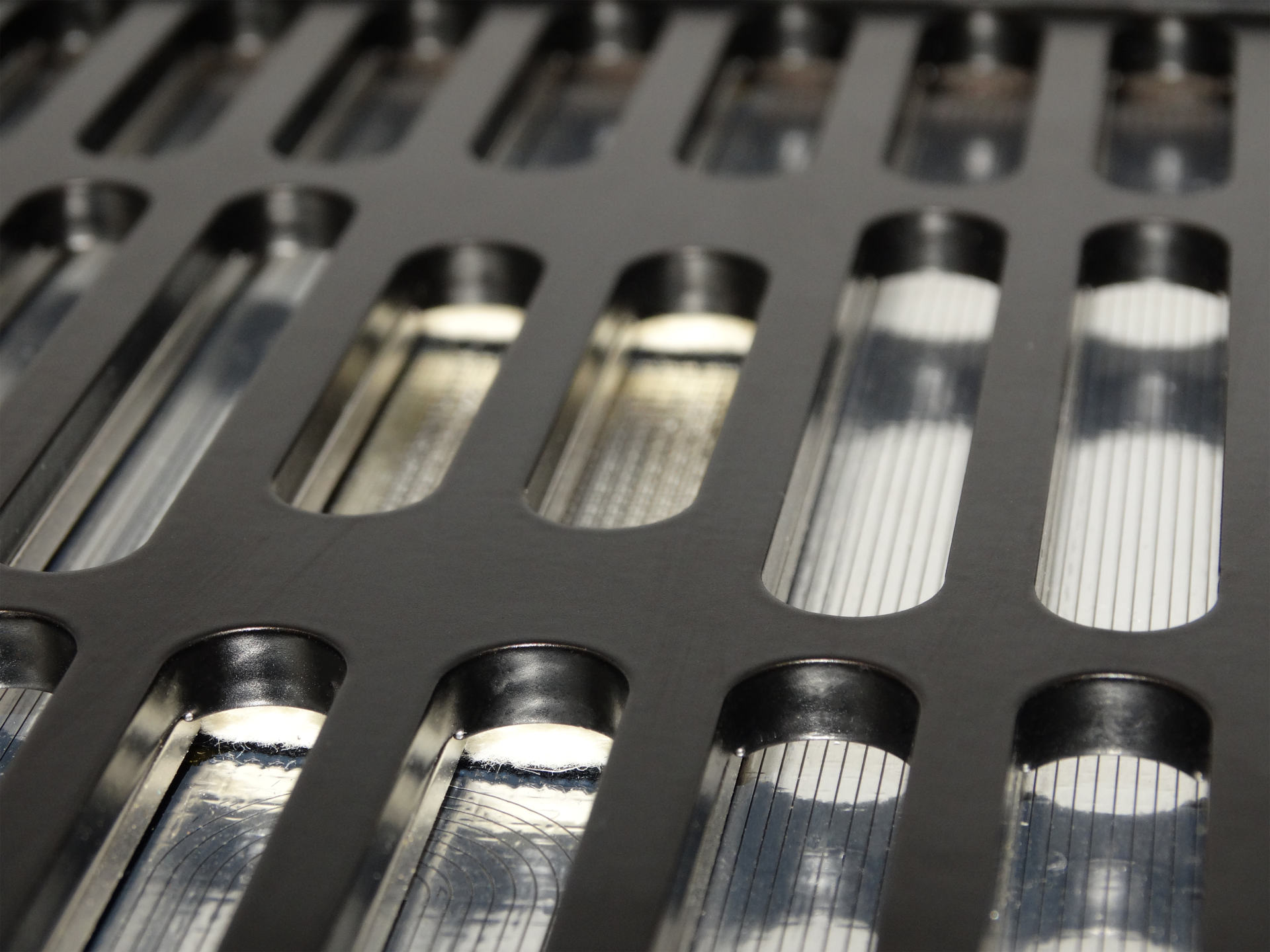

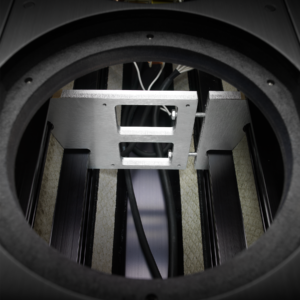

Picture 1: First generation

Picture 2: Second generation

Did you touch the speaker’s core, the coax mid-high range driver?

Yes, of course. That’s where we made the most significant changes. An additional neodymium magnet above the tweeter gives it a higher efficiency, particularly in the Coax 811 – with pretty cool acoustic results. The front panel has been stiffened with an extra cross-bracing so the magnets could be “soft” glued, eliminating annoying resonances.

Exclusively, a newly developed special coating on the foil is used. This linearizes the frequency response in the lower transmission range and allows a lower transition to the woofer. The coax driver thus emits sounds from 450 Hz. The sensitive range of vocals is reproduced flawlessly, contributing to a well-balanced and neutral sound pattern.

Picture 1: First generation

Picture 2: Second generation

That sounds like a great deal of effort! Does it reflect in the result?

It certainly does!

Our coaxial ribbon system offers advantages you can’t find in ordinary midrange drivers for love nor money.

The speaker’s “engine” is simultaneously its membrane and thus the sound generating part. This guarantees a fantastic performance – a great deal of horsepower per kilogram!

In addition, the tweeter and midrange drivers have been arranged coaxially on one level. This creates a point source at which the position of the sound reproduction remains unchanged across a wider frequency range, which is ideal for natural vocals. In reality, a voice only comes from one point, after all.

How is your development team structured? Is Kurt Scheuch still involved after his retirement?

Conceptually, yes.

Many of the innovations were initiated by Kurt. And he was a most valued critical discussion partner throughout the entire optimization process.

The operational responsibility used to lie in the hands of one or two people. Today – even on a passive loudspeaker – an entire team is involved. You’ll need a concept, design, construction, acoustics, procurement, marketing, etc. Everyone has to cooperate and work as a functioning entity. And the more versatile a team, the more opinions clash. This might not make the process any easier, but the outcome is all the better.

Especially in a small company like PIEGA, this team spirit is tremendously important, and we are lucky enough to have plenty of it. A clear division of responsibilities allows everyone to strive in their area of expertise. Agile project management also offers the potential to run several projects in parallel and to react quickly and, above all, in a controlled manner to changing parameters.

Currently, we run five projects at PIEGA. And no, I’m not giving away what we will launch next.

What do you think was the biggest challenge in this development process?

There are challenges in any new development. And sometimes, there are nasty surprises, such as the pandemic, which caused a lot of procurement difficulties for PIEGA. Delays in our supply chain have massively complicated the development and manufacturing process and significantly dragged out the road to the final product. I guess a loudspeaker has yet to be built working from home.

But our real challenge was: how to perfect a true classic?

Our goal was to highlight and emphasize this speaker’s remarkable core. It’s not the conceptual changes but the details that define a product. The Coax, like every PIEGA loudspeaker, is also a design piece. The predecessor Coax series remained untouched for many years, yet it still stands the visual test of time. That’s why we have decided to keep the previous Coax models in a Coax LTD series.

But whoever sees them next to the new series is immediately aware that the design has evolved, and so has the sound. The “old” Coax is a fascinating speaker. But with the new series, the team has taken another big step up the ladder.

And finally, what makes the coaxial speakers unique from their creator’s point of view?

Personally, I think it’s the story behind the speaker. The meticulous craftsmanship and precision from planning to handmade manufacturing make the difference.

Please wait while we redirect you to PIEGA USA.

Please wait while we redirect you to PIEGA USA.