Sound controlling components of HiFi loudspeakers.

SOUND CONTROLLING COMPONENTS

2019

your PIEGA Team

A loudspeaker consists of a number of individual components that are combined into different assemblies and elements. The loudspeaker is built out of these in its entirety. In principle, each component of a loudspeaker has an effect on the sound characteristics – however, these vary greatly, as shown by the following considerations.

These characteristics are divided into primary components (loudspeaker chassis, frequency crossovers, cabinet) that affect the sound and secondary components (terminals, cables, etc.).

Membranes

On every loudspeaker chassis, i.e. bass loudspeakers, midrange ribbons and also tweeters, the membrane is the component that produces the sound. It has the task of converting the electrical energy into sound waves and following the signal as accurately as possible. For this reason, it is very important for the membrane to operate like a piston at any volume and in the entire frequency range it transfers without any deviating movement (wobble, twisting, juddering, resonances). When you consider that even the smallest movement of a membrane in the thousandth of a millimeter range can produce a clearly audible sound, the importance of maximum accuracy in membrane movement becomes clear.

What is required to ensure this is very complex. The greatest difficulty here is also the fact that it is not possible to compensate for “faulty” membrane movement. Incorrect membrane movement cannot be balanced out or prevented through equalization or any other digital compensation. This is why it is therefore even more important when designing a loudspeaker to pay special attention to the correct operation of the membranes in all operating states. A demanding task, since the membranes are exposed to extreme accelerations and pulses, and also have to correctly reproduce dynamic elements in relation to frequency and time.

The membrane material can vary greatly here. Today, metals such as aluminium, beryllium or titanium, plastics such as polypropylene or carbon fiber, compounds, different ceramics and even paper are used. Combinations of different materials are also frequently used. Because there is no such thing as an ideal membrane material for all applications, the designer must select the ideal membrane, its structure and design according to the application involved, its size and principal purpose.

The membrane and its fault-free operation are the central prerequisites of perfect music reproduction. However, every chassis also contains other components that affect the sound. For example, the membrane suspension (corrugation and centering) and the magnet system (the design of the magnet, the electrodynamic properties of a chassis). These factors, which are also called the Thiele/Small parameters, determine together with the cabinet the transfer characteristics of the chassis when mounted.

Ribbon technology

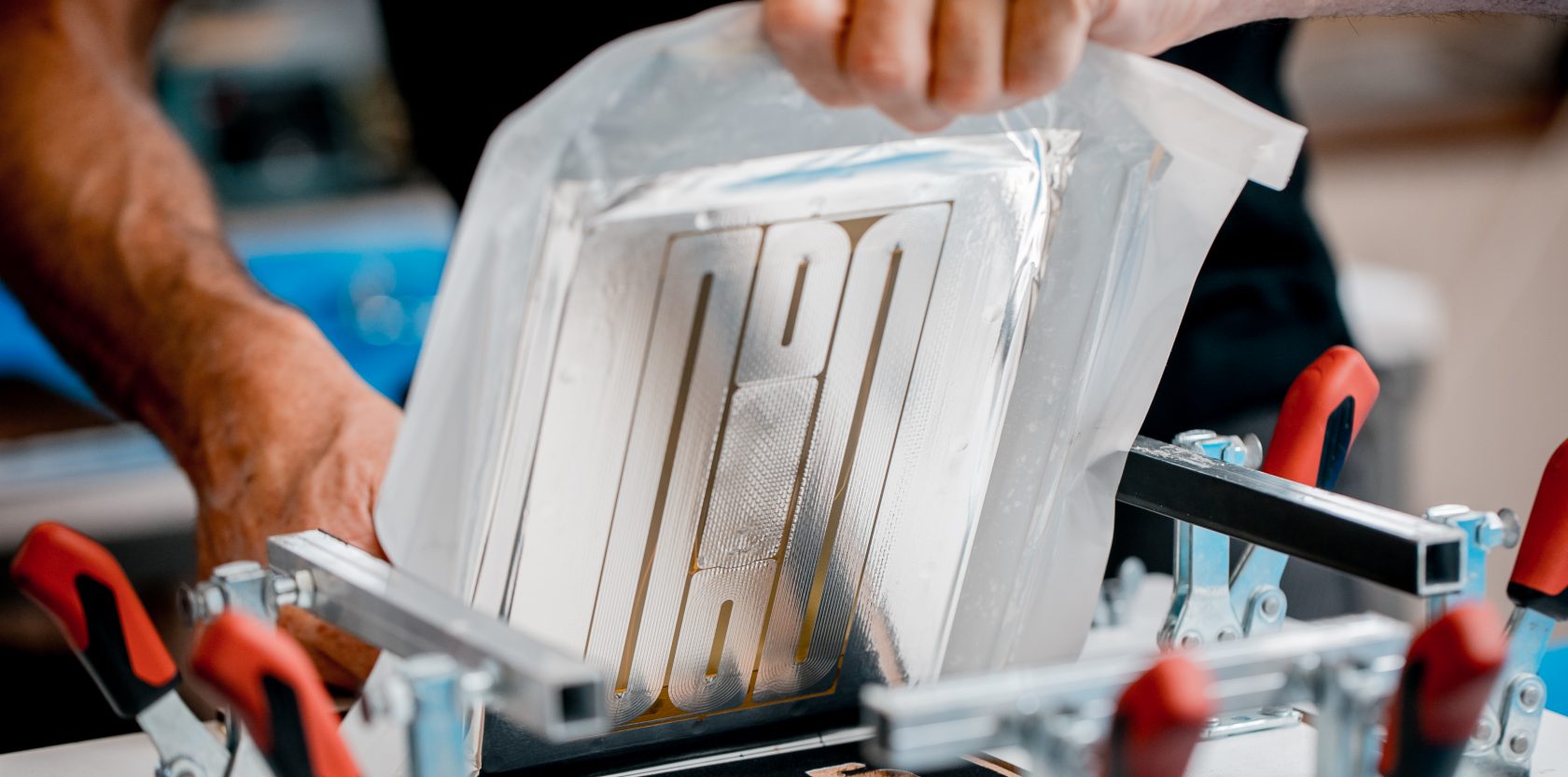

Obviously, the midrange and high frequency range processes much faster pulses and much higher frequencies than in the bass range. It is therefore very important to keep the moving masses in these chassis as small as possible. Ribbon technology is therefore the ideal sound system solution used here.

The ultra-thin aluminium foils of ribbon tweeters and midranges are only a fraction of the weight of conventional cone and dome membranes. Thanks to their even drive in all operating states they nevertheless operate as pure piston radiators. Although these systems involve the use of more expensive material and greater manufacturing effort, the listener is more than rewarded by the unsurpassed sound reproduction quality achieved.

Loudspeaker drivers, regardless of whether they are for bass, midrange or tweeter loudspeakers, are highly complex structures in all cases, which form the foundation for a high quality loudspeaker.

Frequency crossover

In a loudspeaker with several chassis, the audio signal coming from the amplifier is split into the different channels (bass, midrange and high frequency range). This is normally performed by a frequency crossover consisting of coils, capacitors and resistors. It has the task of assigning each part of the frequency range correctly to the individual chassis designed for that range. At the same time it ensures that the sum of all loudspeaker signals corresponds as closely as possible to the original signal. Frequency crossovers are therefore very complex, but can be calculated very precisely today with modern measurement and simulation Systems.

Cabinets

Even though it is the membrane movement in the individual chassis that produces the sound waves, the cabinet also has an important role to play here: The dimensions and the volume of the cabinets must firstly precisely match the requirements for the interaction with the chassis. On the other hand, the ideal loudspeaker cabinet must not in any way be subject to distortion or resonate or move at specific frequencies. Ideally, the loudspeaker cabinet must be as solid as a rock in order to provide a stable foundation for radiating the sound and thus ensuring outstanding audio quality.

As soon as a loudspeaker cabinet noticeably vibrates, it also radiates sound which is overlaid on the sound waves emitted from the membranes, thus resulting in undesired signal peaks or cancellations. Another difficulty is that parts of a cabinet that were set in motion continue to vibrate for a certain time due to their mass, even if the generating pulse has already disappeared. This causes blurring effects both in the frequency as well as the pulse response.

Due to the reasons stated above, the perfect loudspeaker cabinet should be extremely rigid and the cabinet material should be as well damped as possible. In this respect, aluminium is almost the ideal material. Cabinets that are used in combination with accurately deployed stiffeners and the correct damping material can offer virtually perfect characteristics at a fraction of the required wall thickness compared to cabinets made from other materials such as MDF. The extruder technology also enables virtually any imaginable and acoustically ideal shape to be produced. Aluminium is therefore a brilliant cabinet material for making cabinets without any “inherent sound”.

Peripheral components

The other components, such as the internal cabling, connection terminals or adjustable stands do not actually present any problems and are easy to define. Consideration only has to be given to the electrical characteristics and long-term durability, such as the possible oxidization of contacts. Depending on the condition of the floor, there are other, albeit limited, possibilities to control the transmission properties of a HiFi loudspeaker, such as with spikes or screwable damping elements.

A loudspeaker therefore consists overall of several individual parts that sometimes have to meet extreme requirements. Whatever the case, painstaking design, careful selection of the materials used, as well as precise production are of central importance.

Please wait while we redirect you to PIEGA USA.

Please wait while we redirect you to PIEGA USA.